|

|

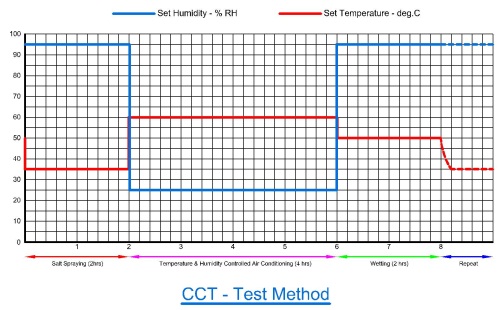

The Cyclic Corrosion

Test Chamber (CCT )are designed to program control the

following test

- Salt spray

- Condensation humidity

- Controlled humidity air

drying

- Fog spray

- Standard meet ASTM, BS, DIN, ISO,

IEC, MIL STD, NATO STANAG, GMW, JASO, VDA, GM, VW, Toyota, Renault, Volvo etc

Option

- Liquid immersion

-

SO2 gas dosing

-

Ultra low temperature (-20C, -40C)

|

Features

- LCD touch screen controller

- User friendly operation

- Fix mode & program mode

(20 program, 20 segement , with repeat function)

- 3 standard test mode: Salt spray, condensation

humidity (wetting), controlled temperature/humidity air

drying

- Option test mode: wall washing, liquid

immersion, ultra low temperautre, SO2 gas dosing

- Temperature/humidity range:

20-80C (100C option) /20-100%RH

- Automatic air purge

- Pneumatic canopy opening

- Flexible samples racks for different types of samples

- Large capacity salt spray reservoir

-

With exhaust and drain connection

- With entry port

-

With glass window

- With castors

- With datalogging

function (USB)

- RS232 interface

- Calibration certificate

-

Comply to

international standards:

ASTM B117, ASTM B368, ASTM B380, ASTM D1654, ASTM D1735,

ASTM D2247,

ASTM D2803 , ASTM D3451 , ASTM D4585 , ASTM D5894 , ASTM

D6577 , ASTM D6675 , ASTM G43, ASTM G5894, ASTM G85

,

BS 2011, BS 3900 , BS 5466, BS 7479, EN 60068, EN 60512,

EN ISO 4541, EN ISO7253, DIN 50.017 , DIN 50.021,

DIN 50.012

, GM4465P

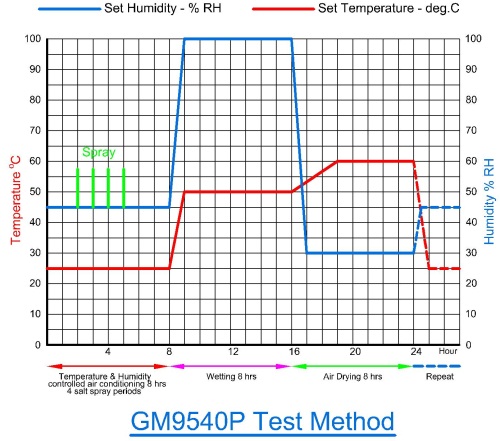

, GM 4298P , GM 4465P , GM

9540P , GMW 14729 (Option A) , GMW 14872 , GMW 3286

,

IEC 60068, ISO 3768, ISO 3769, ISO 3770, ISO 7253,

ISO9227,

ISO 9227 , ISO

16701 , ISO 60082 . ISO 6270-2 , ISO 9227,

ISO 11997,ISO 14993,

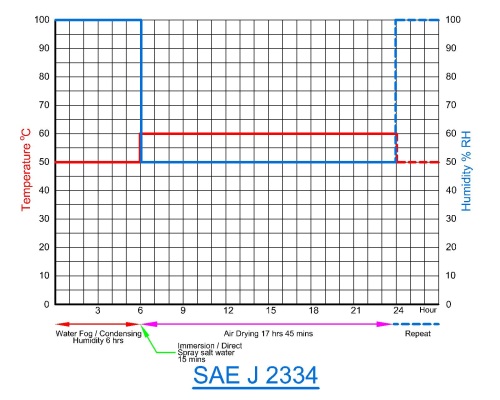

JIS H8502 , JIS Z2371 , SAE J1959 , SAE J2334 ,

MIL-STD-202, MIL-STD-750, MIL-STD-810G,NATO STANAG

4370, Ford CETP 00.00-L-467 , Ford FLTM BI 103-01 , Ford

FLTM BI 104-01 , Ford FLTM BI 104-02 , Ford FLTM BI 123-03

, Ford FLTM BQ 105-01, Honda HES D6001, Honda HES D6501,

Honda HES D6501, Mazda MES MN601 , Mazda MES MN601, MCT-2M

, Mazda MES MN601, MCT-3M , Nissan CCT-I – NES M0158 ,

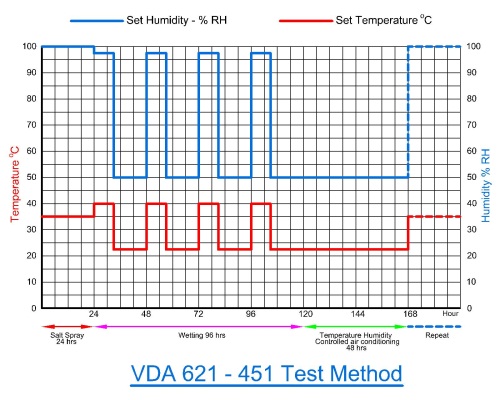

Renault ECC1 - D17 2028 , Toyota TSH 1555G , Volvo STD

1027,1375 , Volvo STD 423-0014 , Volvo VCS 1027-14

|

Standard salt

spray testing

- Temperature control

-

Salt spray test

- Condensation test

- Air purge

|

|

|

|

Controlled temperature

and humidity

- Temperature: 20-80C

(option: 100C)

-

Humidity: 20-99%RH

Option

- Temperature: -20C or

-40C

|

|

|

Liquid Immersion

(option)

- Liquid temperature:

Rm to 70C (controllable)

- Include water pump

- SAE J2334

|

|

SO2 gas dosing

(option)

- SO2 range: 25 to

1000ppm

- 35cm2/min/m3

-

ASTM G85 Annex 4

|

|

Rotating spray

bar

(option)

- Direct spray

- Rotatable (option)

- Time control by

program

|

|

|

|

UV lamps

(option)

- UV lamp: UVA-340 or UVB-313

- UV Range: 0.35 to

1.5W/m2 (adjustable)

|

|

|

|

|

Standard Features |

|

|

Model |

JTH-CCT500 |

JTH-CCT1000 |

JTH-CCT1500 |

JTH-CCT2000 |

|

Internal Dimension (mm) HxWxD |

600x1000x700 |

700x1650x900 |

800x2100x900 |

1350x2180x980 |

|

External Dimension (mm) HxWxD |

1510x1580x1090 |

1790x2265x12800 |

1790x2711x1280 |

2950x1200x1800 |

| Temperature in

Chamber |

20 to 80C +/-1degC

(option 100C) |

| Humidity in

Chamber |

20 to 100%RH +/-3%RH |

| Temperature in

Air Saturated Tank |

Rm to 70C +/-1degC |

| Salt Spray rate |

0.5 to 3ml/80cm2 (adjustable) |

| Condensation |

100%RH at the range of 30 to 60C (adjustable) |

|

Capacity |

500L |

1000L |

1500L |

2000L |

| Salt Solution Tank |

100L |

100L |

100L |

100L |

| No. of sample

racks |

6 |

10 |

14 |

16 |

|

Data

Storage |

USB

(option) |

| Air Connection |

4 to 6 bar |

| Water

Connection |

0.5 to 5 bar |

| Power

Supply |

1phase

240ac 50/60Hz |

| Standard |

ASTM, BS, DIN, ISO,

IEC, MIL STD, NATO STANAG, GMW, JASO, VDA, GM, VW, Toyota, Renault, Volvo etc |

Option:

- With USB data storage

- Low temperature: -20C or -40C

- SO2 gas dosing

- Rotating spray

- UV lamps (UVA-340 or UVB-313)

Noted: Custom size available on request

| |