|

|

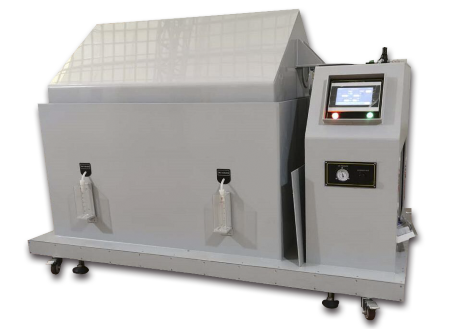

The Salt Spray

Chamber are specialized to test the performance of the

products for its surface of various materials after

treatment of corrosive protection by means of painting,

coating, galvanizing, anodizing and of

lubricant.

- Comply to

international standards: CNS3627, 3885, 4159, 7669,

8886, JIS Do201, H8502, H8610, K5400, Z2371, ISO3768,

3769, 3770, 9227, ASTM B117, B268

- Capacity: 110, 270,

480, 640L

|

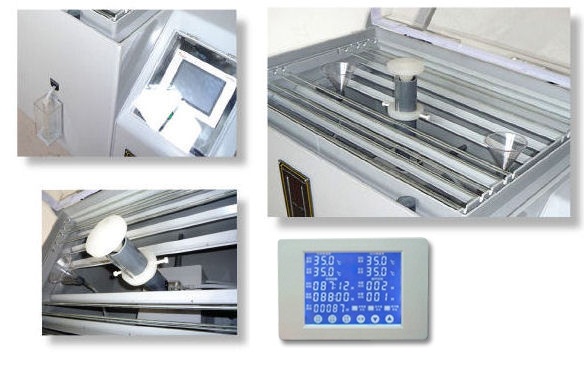

- with LCD touch screen controller operation, PID control

with 0.1C precision

- auto water supply when the water is too low

- precise Pyrex it falls on the surface of the products

being tested the difference of fallen mist preese pyrex

guarantees no crystallized salt

- with double over-heat protect and water low alert to

ensure safety

- with timer control

- with thermometer

- spray tower with cone sprayer, to direct fog, regulate

fog amount make the fog dispersing evenly

- hanter principle is used to make the saturated air hot

and moist to keep the humidity in the test chamber

| Model |

SP110 |

SP270 |

SP510 |

SP960 |

SP1440 |

| Internal Dimension (cm), WxDxH |

60x45x40 |

90x60x50 |

120x85x50 |

160x100x55 |

200x120x60 |

| External Dimension (cm), WxDxH |

105x63x107 |

138x91x128 |

220x120x145 |

260x145x155 |

300x165x160 |

| Temperature in

Chamber |

NSS ACSS 35degC+/-1degC / CASS

50degC+/-1degC |

| Temperature in

Air Saturated Tank |

NSS ACSS 50degC+/-1degC / CASS

63degC+/-1degC |

| Capacity |

110L |

270L |

510L |

960L |

1440L |

| Salt Solution

Tank Size |

15L |

25L |

40L |

50L |

80L |

| Power

Supply |

220-240Vac

50/60Hz |

| |