| HOME | CATALOG | REQUEST QUOTE | NEWS |

|

Explosion-protected information

Area classification Hazardous areas are classified into zones based upon the frequency of the occurrence and duration of an explosive gas atmosphere.

The gas area is classified into three zones: zone 0, zone 1 and zone 2. Zone 0: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods. Zone1: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally. Zone2: A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally but, if it dose occur, will persist for a short period only. As a rule, "for a short period only" means up to 2 hours.

The dust area is classified as three zones: zone20 , zone 21 and zone 22. Zone 20: Area in which combustible dust, as a cloud, is present continuously or frequently, during normal operation, in sufficient quantity to be capable of producing an explosive concentration of concentration of combustible dust in mixture with air and /or where layers of dust of uncontrollable and excessive thickness can be formed. Zone21: Area not classified as zone 20 in which combustible dust, as a cloud, is likely to occur during normal operation, in sufficient quantities to be capable of producing an explosive concentration of combustible dust in mixture with air. This zone can include, among others, areas in the immediate vicinity of powder filling or emtying points and areas where dust layers occur and are likely in normal operation to give rise to an explosive concentration of combustible dust in mixture with air. Zone22: Area not classified as zone 21 in which combustible dust clouds may occur infrequently and persist for only a short period, or in which accumulations or layers of combustible dust may be present under abnormal conditions and give rise to combustible mixtures of dust in air. Where, following an abnormal condition, the removal of dust accumuations or layers cannot be assured, then the area is to be classified zone 21.

Substantive language 1. Isolation explosive electric equipment Withstanding for explosion pressure from interior mixed air also avoiding it spread out to exterior mixed air, marked "d". 2. Increasing safety electric equipment In normal condition, it's withoutelectric arc spark and high temperature up to ignite mixturer, it's structure adopts, safety step to avoid appearing electric , spark and high temperature, mark "e" 3. Powder and dust electric equipment On stated condition the enclosure can prevent dust entering or the interior dust will not ignite mixed air, so that ensure the surrounded explosive mixed air will not be ignited Noted: 1. Dust explosive electric equipment and air explosive electric equipment temperature classes is the same. 2. According to America and Europe standard difference. There are two kinds, the test ways of A and B is different, but protective class is the same.

Temperature class

Explosive mark exemplify 1. Class II B, group T3 isolation explosive electric equipment, mark "Exd II BT3" 2. Class II, group T2 increasing safety explosive electric equipment, mark "Exe II T2" 3. It adopts multiple type, first mark main explosive proof type. Then mark other explosive-proof type. The main body adopt increasing safety and built-in class II C isolative explosion parts, temperature T4, mark "Eexd II CT4", if main part adopts isolative explosive II BT4, other adopt increasing safety, then it marks "Exde II BT4" 4. DIPA20TA T4, DIP means dustignition explosion-proof A20 means type A explosive-proof equipment and used for Zone 20, TA T4 means temperature T4 (135C)

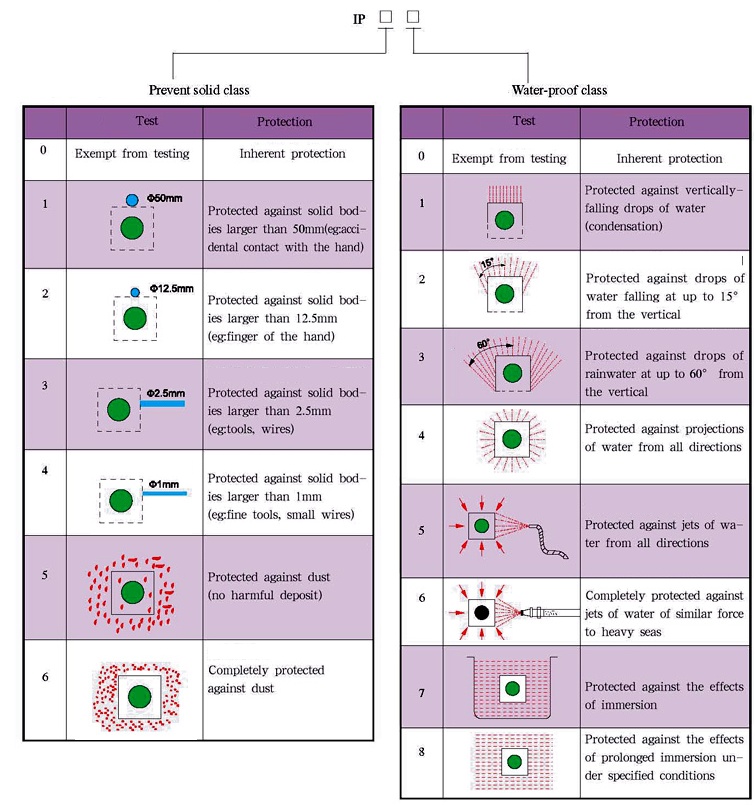

International Protection code

____________________________________________________________________________________________________

| |||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Welltech

Instrument Co. Ltd |

I am God Almighty; walk before me and be blameless. (Genesis

17:1)